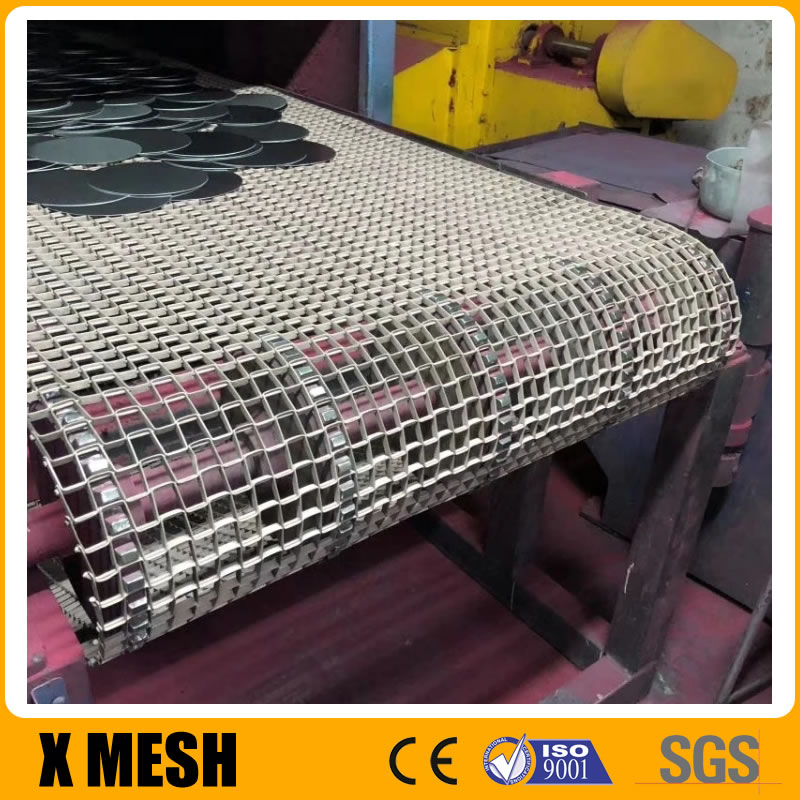

Hebei Qijie Wire Mesh MFG Co., Ltd. specializes in durable and versatile Honeycomb Conveyor Belts, also known as Flat Wire Belting. These belts are known for their strong yet lightweight design and open mesh construction. They provide a flat surface for conveying and are made from flat wire strips joined by cross rods, ensuring they run straight and perform reliably. Ideal for a variety of industrial uses like food processing, freezing, baking, drying, and packaging, these belts enhance airflow and circulation around products. This makes them efficient for applications needing good air flow and temperature resistance. Hebei Qijie’s belts are a top choice for businesses looking for durable, flexible, and efficient conveyor solutions.

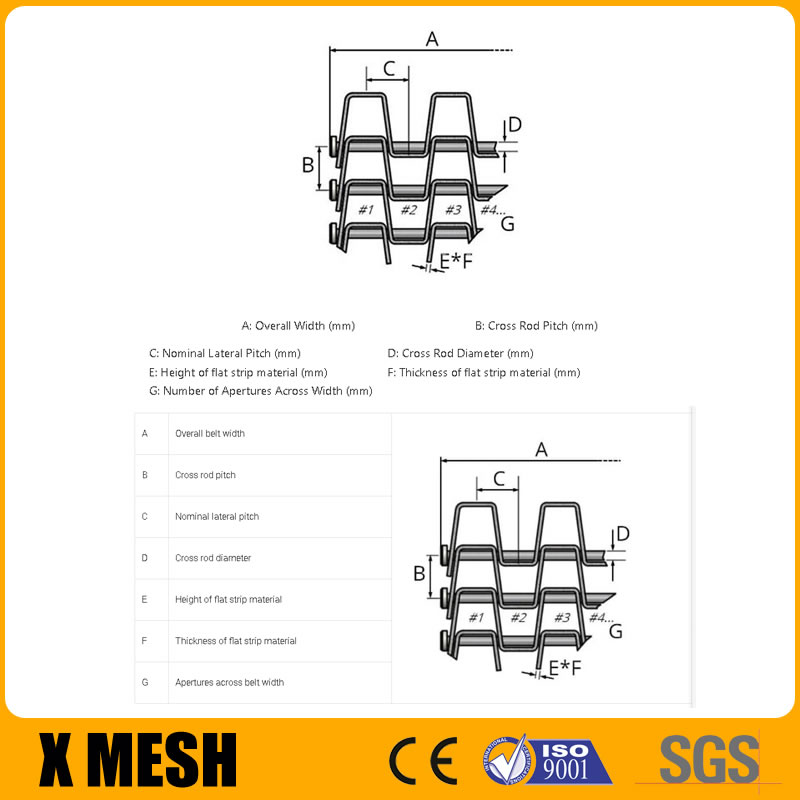

Design:

- Design Efficiency and Strength

Honeycomb conveyor belts are ingeniously crafted for lightweight yet strong performance, with a high strength-to-weight ratio. This design allows them to handle significant loads while being easy to operate and maintain. - Customization and Versatility

These belts are adaptable, available in various sizes and with optional additions like side plates or flights, catering to a range of industrial needs. Their large open area is ideal for processes needing quick drainage and air circulation, making them suitable for industries involving drying, cooling, or washing. - Functionality and Application

Designed for easy joining and maintenance, these belts can be driven by customizable stainless steel or nylon sprockets, enhancing their versatility in different industrial settings. This adaptability makes them ideal for a variety of applications, including food processing, pharmaceuticals, and packaging.

Benefits:

- Long-lasting, with double the lifespan of many similar belts.

- Easy installation without the need for special tools.

- Excellent belt tracking due to positive drive.

- Up to 81% open area for efficient flow-through.

- Available in widths up to 150 inches.

- Strong edge design reduces snagging.

- Flat surface and open mesh design for easy cleaning and maintenance.

- Edges with welded rings or clinched edges for stability.

Materials

- Honeycomb conveyor belts, known for their versatility, are available in a variety of materials including high carbon steel, galvanized steel, and both 304 and 316 stainless steel. This range of materials makes them adaptable to diverse industrial uses. High carbon steel belts are prized for their strength and are ideal for applications like casting where robustness is essential.

- Galvanized steel, treated with a protective layer of zinc, is suitable for environments prone to moisture or corrosive elements, making it a good choice for drainage applications. The 304 and 316 grades of stainless steel offer excellent corrosion resistance and durability. These stainless steels are especially beneficial in food-related applications, such as baking and food packaging, due to their non-reactive nature with food substances.

- In particular, food-grade stainless steel, like SUS304 and SUS316, is specifically used for food conveyors, ensuring safety and compliance with food industry standards. The selection of the appropriate material for a honeycomb conveyor belt is crucial and depends on the specific requirements of the application, including factors like temperature resistance, corrosion resistance, and strength.

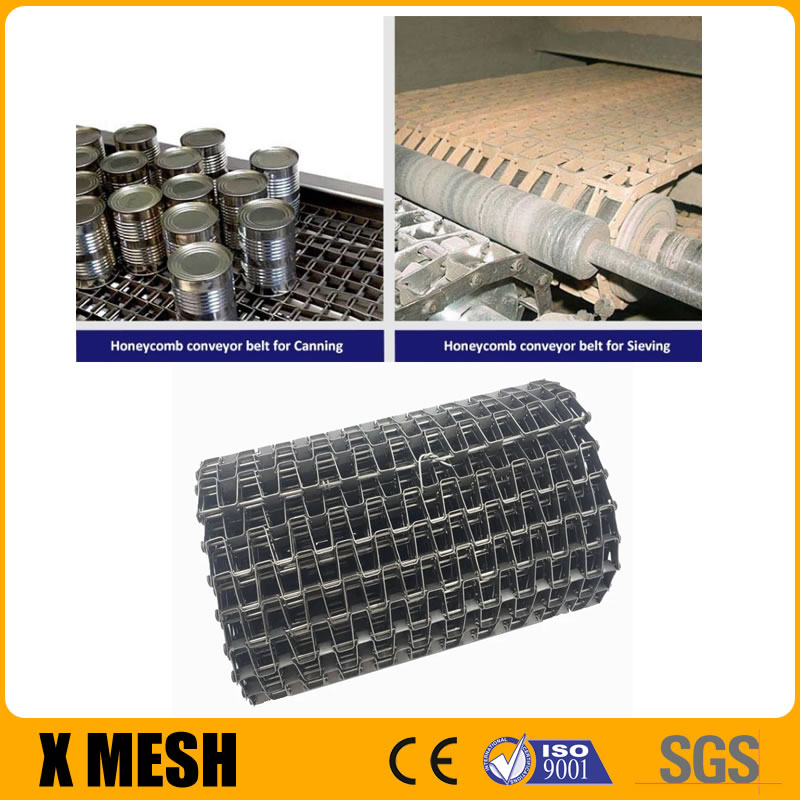

Applications of Honeycomb Conveyor Belts

- Temperature-Resistant Uses: These belts excel in environments requiring temperature resistance, making them perfect for processes like stoving, heating, cooling, drying, or sterilizing. Their ability to withstand different temperatures allows for use in various temperature-sensitive applications.

- Food Processing: In the food industry, these conveyor belts are widely used in cooking, baking, freezing, proofing, and packaging systems. Their design and material choices make them ideal for different stages of food processing.

- Industrial Processes: They are also integral to various industrial processes, including washing, sorting, recycling, elevating, and assembly. The belts’ versatility and strength enable them to support these diverse operations effectively.

- Specialized Systems: Beyond standard applications, honeycomb conveyor belts are used in specialized systems like weed clearing, turf cutting, sieving, bread production, and waste handling. This showcases their adaptability to specific and unique industry needs.

- Replacement and Maintenance: Replacing these conveyor belts is straightforward. To ensure correct sizing and features for replacement, measurements of the existing belt or a sample piece are typically used. This ease of replacement and maintenance adds to their practicality in various application scenarios.

Honeycomb Conveyor Belts types of Edges

- Welded Edges: These provide a strong, smooth finish by welding the belt’s edges, ideal for high-tension or high-movement applications.

- Clinched Edges: In this design, edges are bent and flattened for safety, reducing snagging risks, commonly used where the belt interacts with other equipment.

- Chain Edge: This type includes a metal chain along the belt edges, enhancing load support and stability, especially suitable for longer conveyor systems.

Each edge type caters to specific needs, such as strength, safety, or stability, and is chosen based on the belt’s application and operational environment.

Honeycomb Conveyor Belt Specifications

Honeycomb Conveyor Belt Standard Specifications

- Cross Rod Pitch (mm):

Options include: 13.7, 26.2, 27.4, 28.6, 28.4 - Nominal Lateral Pitch (mm):

Available sizes: 14.6, 15.55, 15.7, 24.7, 15, 26.25, 22.5 - Flat Strip (mm):

Variants: 10×1, 12×1.2, 9.5×1.25, 15×1.2 - Cross Rod (mm):

Sizes: 3 and 4

European Standard table for Honeycomb Conveyor Belts

| Cross Rod Pitch (mm) | Nominal Lateral Pitch (mm) | Flat Strip (mm) | Cross Rod (mm) |

| 13.7 | 14.60 | 10×1 | 3 |

| 26.2 | 15.55 | 12×1.2 | 4 |

| 27.4 | 15.70 | 9.5×1.25 | 3 |

| 27.4 | 24.70 | 9.5×1.25 | 3 |

| 28.6 | 15.00 | 9.5×1.25 | 3 |

| 28.6 | 26.25 | 9.5×1.25 | 3 |

| 28.4 | 22.50 | 15×1.2 | 4 |

| This configuration is tailored for applications where button edges (welded washers) are required, offering a combination of robust performance and compatibility with specific conveyor system requirements. | |||

Individual and Custom Specifications:

Conveyor belts can be customized up to 5 meters in width, with alternative specifications available upon request. Qijie Co. offers the flexibility to create custom-built specifications within a certain framework. For unique requirements, especially regarding the flat strip section size, consultation with Qijie Co.’s Technical Sales Engineers is advised to discuss detailed specifications. Custom samples can be created and sent for testing to ensure the belt meets specific needs.

See pictures for examples

Qijie Model HFCB-001 Honeycomb Flat Conveyor Belts

Qijie Model HFCB-002 Honeycomb Flat Conveyor Belts

Qijie Model HFCB-003 Honeycomb Flat Conveyor Belts

Qijie Model HFCB-004 Honeycomb Flat Conveyor Belts