Hebei Qijie Wire Mesh MFG Co., Ltd. presents EYE-LINK BELTS, a premium collection of conveyor belts that are straight-running and positively driven, ideal for both industrial and food processing applications. These versatile belts feature a wide range of materials, wire diameters, surface treatments, and accessories, making them suitable for diverse conveying needs. The Eyelink modular belts are noted for their strength, stability, and flexible configurations, rendering them perfect for various industries, particularly in food processing.

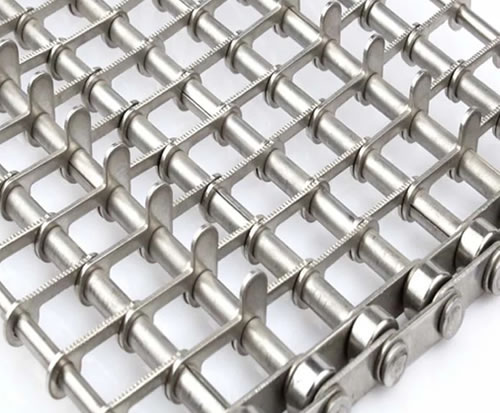

Designed to ensure a straight, smooth run with an exceptionally flat surface, these belts enhance the efficiency of product movement across a wide array of industries. Constructed with durable eye-link modules, plate links, and cross rods, they form a flexible yet robust structure, ideal for heavy-load applications.

Material:

The material options for Eye Link Conveyor Belts can be expanded to include:

- 304 Stainless Steel (T304SS): Known for its corrosion resistance and durability, making it suitable for a variety of food processing and industrial applications.

- 316 Stainless Steel (T316SS): Offers enhanced corrosion resistance compared to 304 stainless steel, ideal for more corrosive environments such as those involving chemicals or saline.

- Carbon Steel: Provides high strength and is cost-effective, suitable for applications where corrosion resistance is not the primary concern.

- Other Materials: Available upon request to meet specific requirements or application needs, ensuring flexibility and adaptability for various industrial uses.

These material options further enhance the adaptability and utility of Eye Link Conveyor Belts, allowing them to cater to a wider range of applications and environments.

Durability Meets Heavy-Duty Performance

Crafted with eye-link modules, plate links, and cross rods, Qijie’s belts offer a flexible, hinge-like structure. This design evenly distributes load and ensures stability and longevity, making these belts perfect for heavy-load applications. They merge a stable carrying surface with the inherent strength of their construction.

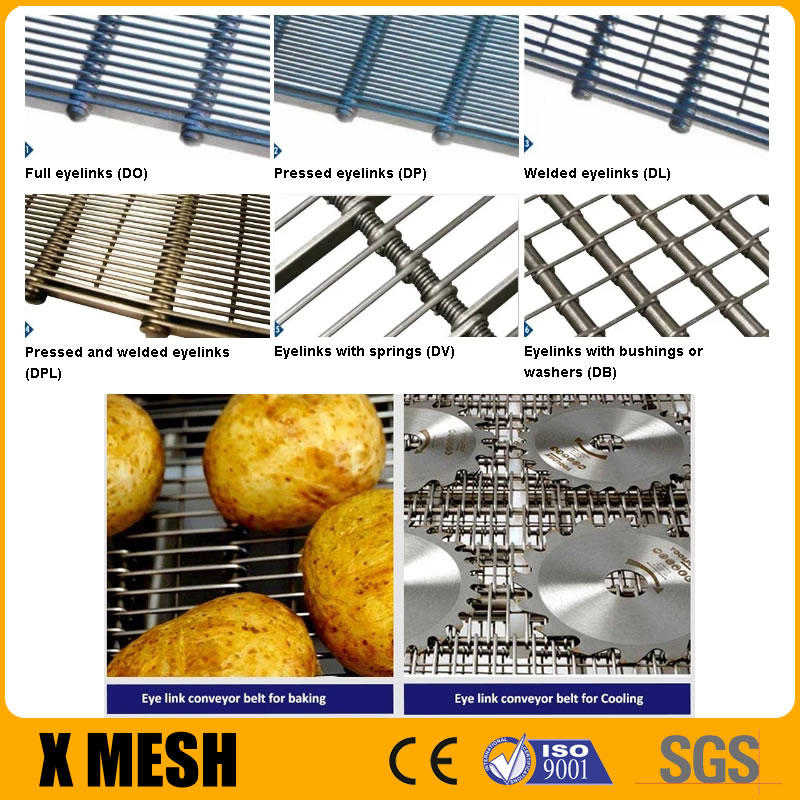

Eye Link Designs

Qijie’s Eye Link Conveyor Belts offer customization, catering to a broad spectrum of industrial requirements. The belts are available in several distinct styles – full eyelink, eyelink with spring, eyelink with rings, and eyelink with underwelded wire – each tailored for specific applications. The full eyelink style, notable for its flow-through properties, is particularly effective in food processing for small product conveyance due to its flat conveying surface and ease of cleaning.

Specialized Eye Link Variations for Enhanced Functionality

- Simplified Overview of Eye Link Conveyor Belt Variations

- Full Eye Links: Belts with closely aligned links for a flat surface, ideal for even conveyance.

- Pressed Eye Links: Belts with flattened links for very small gaps, great for tiny or fine products.

- Welded Eye Links: Belts with links welded to wires, forming flexible modules, easy to clean and suitable for various product sizes.

- Pressed and Welded Eye Links: Sturdy belts with small openings, perfect for stable conveying with minimal gaps.

- Eye Links with Springs: Belts with springs for stability in temperature changes, ensuring effective cleaning.

- Eye Links with Bushings or Washers: Belts designed with gaps for better airflow around products, enhancing process efficiency.

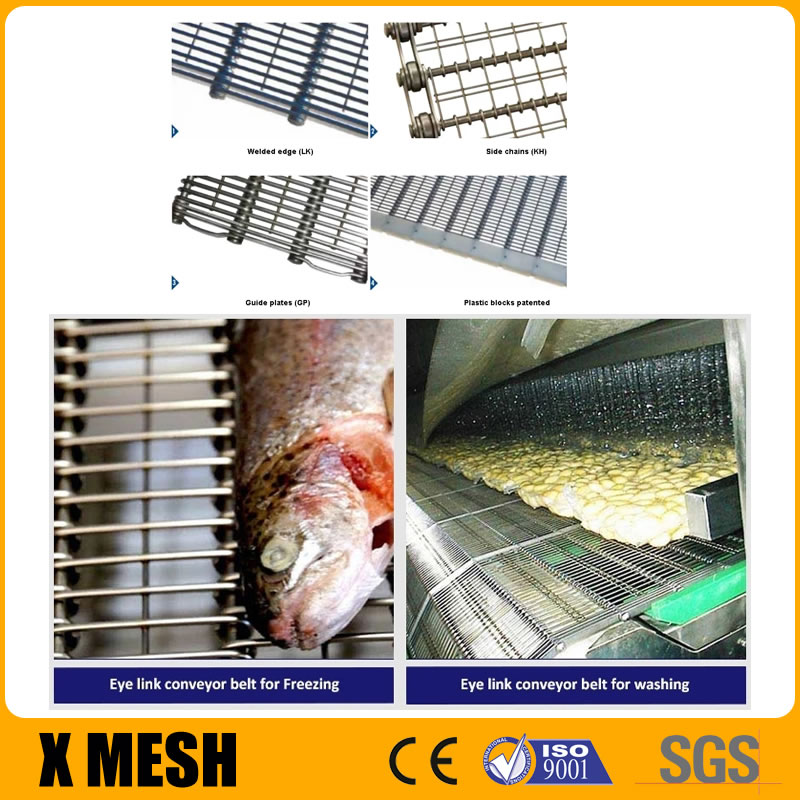

- Eye Link Belt with Welded Edge: Belts with reinforced edges for a polished look and extra support.

- Eye Link Belt with Reinforcing Plates: Strong belts with metal plates at edges, ideal for intensive use.

- Eye Link Belt with Chain Edge: Belts with a chain edge for alternative driving and stable tracking.

- Eye Link Belt with Side Guards: Belts with customizable side barriers to keep products in place, good for organized product lines.

Advantages

- Adaptability for Food Processing: Versatile configurations for diverse food-related applications.

- Robust Construction: Flexible hinge construction ensures even load distribution and strength.

- Customizable Designs: Four construction styles available with additional features like side guard plates and cross flights.

- Ideal for Small Product Transfer: Full eyelink version provides optimal flow-through and a flat surface, especially beneficial for baking processes.

- Industry Versatility: Made from materials like stainless steel, making them suitable for food processing, chemical, pharmaceutical, and packaging industries.

- Variable Wire Spacing and Sizes: Accommodates different applications, with wire spacing ranging from 5/8″ (15.9mm) to 3.0″ (76.2mm) and standard diameters from .064″ (1.6mm) to .126″ (3.2mm).

Applications

- Wide Range of Processes: Including drying, washing, baking, cooling, freezing, pasteurizing, cooking, blanching, and deep-frying.

- Diverse Industrial Uses: Suitable for baking, cooking, cooling, heating, drying, freezing, blanching, washing, frying, sorting, grading, loading, elevating, and more.

- Specific Applications: Designed for use in tunnel freezers, drying, cooling, cooking, washing, freezing, blanching, baking, pasteurizing, deep-frying, and drainage processes.

Functional Enhancements for Diverse Applications

Qijie’s belts come with multiple drive options, including friction-driven cage rollers, positive drive sprockets, and optional chain edge drives. The addition of side guard plates and cross flights, adjustable for product height, further enhances their functionality.

Specific Features for Targeted Applications

- Eyelink with Underwelded Wire: Adjusts to different product types and simplifies cleaning.

- Spring Spacer: Provides stability and shock resistance, ideal for temperature-varying environments.

- Ring Spacer: Allows adjustable airflow between eye-links, tailored to application requirements.

Features

- Single-Level Surface: Prevents product entrapment, eliminating ‘tunnel effect’.

- Flat, Open Mesh Configuration: Simplifies cleaning processes.

- Customizability: Options include side guards, chain drives, and flights.

- High-Temperature Suitability: Compatible with a range of steel specifications.

- Durable and Strong: Ideal for heavy-duty usage with a smooth, layer-free surface.

- Air and Fluid Drainage: Excellent drainage capabilities, reducing process interference.

- High Strength and Carrying Capacity: Suitable for substantial loads.

- Modular Design: Offers a flat surface profile for versatile use.

- Long Lifespan: Reliable even in 24/7 heavy-duty production environments.

- Multiple Drive and Spacer Options: Accommodates various industrial needs.

- Efficient Maintenance: Designed to reduce downtime and maintenance requirements.

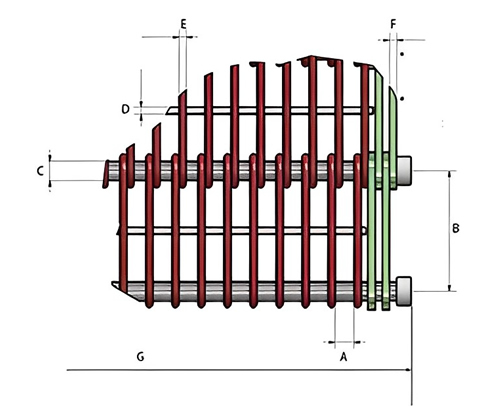

Specifications of Eye Link Conveyor Belts

- Dimensions and Capabilities:

Maximum Width: Up to 156 inches (3960mm), accommodating large-scale industrial needs.

Speed Capacity: Capable of operating at speeds up to 200 feet per minute (61 meters per minute).

Temperature Tolerance: Suitable for high-temperature environments, withstanding up to 1000°F (538°C). - Chain and Rod Specifications:

Chain Pitch Options: Available in 25.4 mm, 31.75 mm, 38.1 mm, 50.8 mm, 63.5 mm, and 76.2 mm, offering versatility for different applications.

Rod Diameter Choices: Ranges from 5 mm to 12 mm, providing options for various load requirements. - Wire and Spiral Specifications:

Wire Diameter Range: Includes sizes from 1.5 mm to 3 mm, to suit various product and process demands.

Spiral Pitch Variability: Offers a wide range from 2.4 mm to 100 mm, accommodating different product sizes and types.

Rod Pitch Availability: Comes in 25.4 mm, 31.75 mm, 38.1 mm, 50.8 mm, 63.5 mm, and 76.2 mm, aligning with the chain pitch options. - Belt Width Flexibility:

Range: From 200 mm to an extensive 6,000 mm, ensuring a fit for a broad spectrum of conveyor systems.

A Gap Width (mm) B: Pitch (mm)

C: Cross Rod Dia (mm) D: Underside Welded Wire Dia (mm)

E: Wire Link Dia (mm) F: Reinforcing Plate (mm) G: Overall Belt Width (mm)

Minimum Gap Spacing (mm): Identifies the smallest wire gap in the belt, crucial for material conveyance.

Belt Pitch (mm): Measures the center-to-center distance of two consecutive eye links.

Eye Link Conveyor Belt Without Spacers – Specification Sheet

- Belt Pitch (mm)

Options range from smaller pitches such as 15.875 mm to larger ones up to 100 mm. - Wire Diameter (mm)

Varied options from 1.4 mm to 4 mm to cater to different strength and flexibility requirements. - Cross Rod Diameter (mm)

Ranging from 3.2 mm to 8 mm, providing options for different load-bearing capacities.

Here’s a table corresponding to each specification for the Eye Link Conveyor Belt with Under Welded Wire Spacing:

| Belt Pitch (mm) | Wire Diameter (mm) | Cross Rod Diameter (mm) | Minimum Gap Spacing (mm) | Gap in Steps of (mm) | Maximum No. of Welded Wires |

| 15.875 | 1.8 | 3.2 | 2.0 | 0.1 | 1 |

| 25.000 | 2.0 | 5.0 | 2.3 | 0.1 | 2 |

| 25.400 | 2.0 | 5.0 | 2.3 | 0.1 | 2 |

| 30.000 | 2.0 | 4.0 | 2.3 | 0.1 | 2 |

| 30.000 | 2.0 | 5.0 | 2.3 | 0.1 | 2 |

| 50.000 | 2.0 | 5.0 | 2.3 | 0.1 | 3 |

| 50.000 | 2.5 | 5.0 | 2.8 | 0.1 | 3 |

| 50.000 | 2.5 | 6.0 | 2.8 | 0.1 | 3 |

| 50.800 | 2.5 | 8.0 | 2.8 | 0.1 | 3 |

| 50.800 | 3.0 | 8.0 | 3.3 | 0.1 | 3 |

| 75.000 | 2.5 | 5.0 | 2.8 | 0.1 | 3 |

| 75.000 | 2.5 | 8.0 | 2.8 | 0.1 | 3 |

Here is a table representing the specifications for the Eye Link Conveyor Belt with Springs as Spacers:

| Belt Pitch (mm) | Wire Diameter (mm) | Cross Rod Diameter (mm) | Min Gap Spacing (mm) | Gap Spacing 8mm | Gap Spacing 10mm | Gap Spacing 12mm | Gap Spacing 15mm | Gap Spacing 17.5mm | Gap Spacing 20mm |

| 25.00 | 2.0 | 5 | 7.0 | 8 | 10 | 12 | 15.0 | 17.5 | 20 |

| 25.40 | 2.0 | 5 | 7.0 | 8 | 10 | 12 | 15.0 | 17.5 | 20 |

| 30.00 | 2.0 | 4 | 7.0 | 8 | 10 | 12 | – | – | 20 |

| 30.00 | 2.0 | 5 | 7.0 | 8 | 10 | 12 | 15.0 | 17.5 | 20 |

| 31.75 | 2.0 | 5 | 7.0 | 8 | 10 | 12 | 15.0 | 17.5 | 20 |

| 50.00 | 2.0 | 5 | 7.0 | 8 | 10 | 12 | 15.0 | 17.5 | 20 |

| 50.00 | 2.5 | 5 | 7.5 | 8 | 10 | 12 | 15.0 | 17.5 | 20 |

This table provides a detailed overview of the Eye Link Conveyor Belt with Springs as Spacers, showcasing the variety in belt pitch, wire and cross rod diameter, and the range of gap spacings available. The “-” indicates that a specific gap spacing is not available for that configuration.

Here is the table for the Eye Link Conveyor Belt with Rings as Spacers, detailing the specifications:

| Belt Pitch (mm) | Wire Diameter (mm) | Cross Rod Diameter (mm) | Minimum Gap Spacing (mm) | Gap Spacing can be increased by (mm) |

| 25.00 | 2.0 | 5 | 4 | 2.0 |

| 25.40 | 2.0 | 5 | 4 | 2.0 |

| 30.00 | 2.0 | 4 | 4 | 2.0 |

| 30.00 | 2.0 | 5 | 4 | 2.0 |

| 31.75 | 2.0 | 5 | 4 | 2.0 |

| 50.00 | 2.0 | 5 | 4 | 2.0 |

| 50.00 | 2.5 | 5 | 5 | 2.5 |

| 50.00 | 2.5 | 6 | 5 | 2.5 |

| 50.80 | 2.5 | 6 | 5 | 2.5 |

| 50.80 | 2.5 | 8 | 5 | 2.5 |

| 50.80 | 4.0 | 8 | 8 | 4.0 |

| 60.00 | 2.0 | 5 | 4 | 2.0 |

| 60.00 | 2.5 | 5 | 5 | 2.5 |

| 75.00 | 2.5 | 5 | 5 | 2.5 |

| 75.00 | 2.5 | 8 | 5 | 2.5 |

This table provides a comprehensive view of the various specifications for the Eye Link Conveyor Belt with Rings as Spacers, including belt pitch, wire diameter, cross rod diameter, minimum gap spacing, and the increments by which the gap spacing can be increased.

We also can provide product specifications for the following Eye Link conveyor belts:

Eyelink Belt with Rings as Spacers

Eyelink Belt with Springs as Spacers

Eyelink Belt with Under Welded Wire Spacing

Our specifications cover 9 key aspects:

- Belt Pitch (mm): Measures the center-to-center distance of two consecutive eye links.

- Wire Diameter (mm): Indicates the thickness of the wires forming the eye links.

- Cross Rod Diameter (mm): Specifies the diameter of rods passing through the eye links for support.

- Minimum Gap Spacing (mm): Identifies the smallest wire gap in the belt, crucial for material conveyance.

- Underwelded Wire Spacing (mm): The distance between underwelded wires, providing additional support and determining belt flexibility and strength.

- Maximum Load Capacity: Indicates the belt’s safe weight carrying limit, based on material and construction.

- Temperature Range: Defines the operational temperature range, vital for applications like baking or freezing.

- Materials: Details the type of metal used, affecting the belt’s strength, flexibility, and environmental suitability.

- Surface Treatment: Describes any applied coatings or treatments for extra protection and functionality.

Please note that specific numerical values for these specifications vary based on the manufacturer’s design and the belt’s intended use. If you require detailed values or a range for these parameters, we can provide them via email in a formatted specification sheet.

See pictures for examples

Qijie Model ECB-001 Eyelink Conveyor Belts

Qijie Model ECB-002 Eyelink Conveyor Belts

Qijie Model ECB-003 Eyelink Conveyor Belts

Qijie Model ECB-004 Eyelink Conveyor Belts