Hebei Qijie Wire Mesh MFG Co., Ltd. is renowned for its Biscuit Baking Belts. Tailored for the bakery industry, these belts are perfect for directly baking biscuits in straight-feed-through ovens. They boast a lightweight, stratified metal spiral design with reduced thickness for low heat inertia and high strength. The belts ensure effective air circulation and feature a wire superposition and open mesh with looped edges. Constructed from specially chosen carbon steel for uniform baking, they function optimally at temperatures between +200ºC and +275ºC, with a stainless steel version also available.

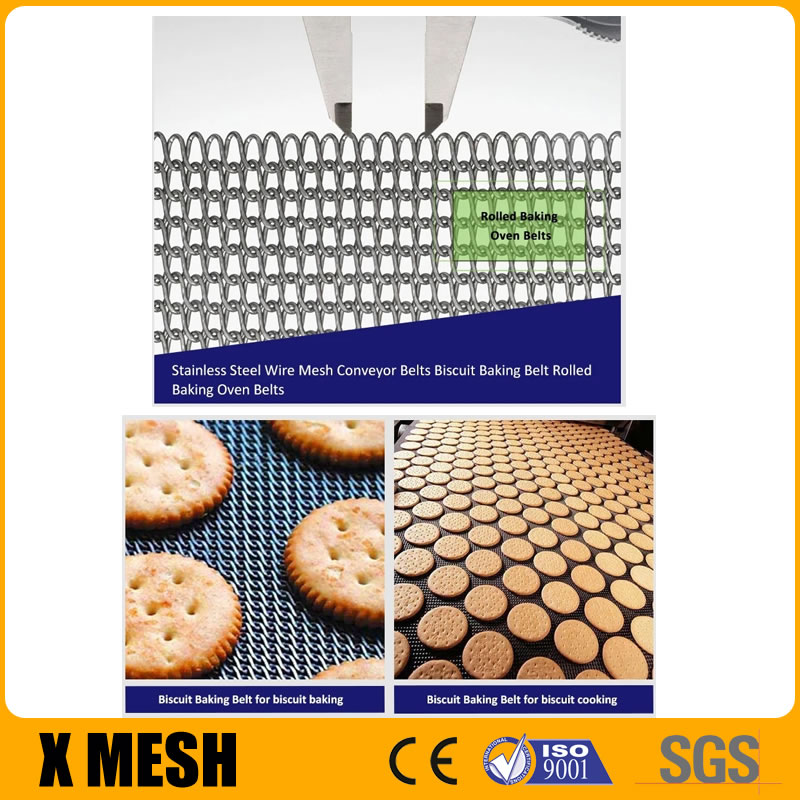

The Rolled Baking Band, also known as the Biscuit Baking Belt or Z Belt, is essential in the bakery industry for biscuit baking. Its flat, even surface effectively transports various dough types, ensuring uniform heat distribution. Ideal for temperatures from +200ºC to +275ºC, it’s made from carbon steel, with a stainless steel option available. However, it’s less suitable for high-fat soft doughs. Additionally, the Baking Band or “Z Belts,” made from materials like carbon steel and brass, offers a durable solution for different baking needs, with specific designs like the Balanced Weave Belt for biscuits and the Compound Weave Belt for finer products. The Flat Roller Baking Belt, thinner than typical belts, is designed for cookie baking plants.

A: Spiral pitch (mm) B: Belt pitch (mm) C: Wire diameter (mm)

Materials

Our Biscuit Baking Belts are made from high-quality carbon steel and stainless steel, offering various wire gauges for different baking requirements.

- High-Quality Carbon Steel: Primarily used in these belts, carbon steel provides excellent strength and durability. It’s particularly suitable for baking processes with temperatures ranging from +200ºC to +275ºC.

- Stainless Steel Option: On request, belts can be made of stainless steel, which offers additional benefits such as corrosion resistance, making it ideal for certain baking environments.

- Wire Gauges: The belts come in various wire gauges, including 16 gauge (1.5 mm), 17 gauge (1.38 mm), 18 gauge (1.2 mm), and 20 gauge (0.9 mm), allowing for customization based on specific baking needs.

These materials ensure the Biscuit Baking Belts from Hebei Qijie Wire Mesh MFG Co., Ltd. are robust, efficient, and adaptable to a range of baking applications.

Applications

These belts are ideal for various baking systems, providing efficient solutions for cooking, heating, and elevating systems. They are widely used in biscuit ovens globally.

- Baking Systems: Ideal for baking biscuits, cookies, and other bakery items. The belts provide an even heat distribution, crucial for consistent baking quality.

- Cooking Systems: Suitable for various cooking processes in industrial kitchens and food processing units.

- Heating Systems: The belts can be integrated into heating systems where uniform heat distribution is essential.

- Elevating Systems: Useful in elevating systems within food processing plants, where the flat and stable surface of the belt aids in the smooth transition of products between different levels.

- Food Processing: In addition to baking, these belts can be used in other food processing stages, like cooling and freezing, due to their temperature-resistant qualities.

- Confectionery Manufacturing: Ideal for transporting confectionery items through different stages of production.

- Dough Handling: The belts’ flat surface is perfect for handling both soft and hard dough types in baking processes.

These diverse applications highlight the versatility and efficiency of the Biscuit Baking Belts in various industrial and food processing environments.

Specification

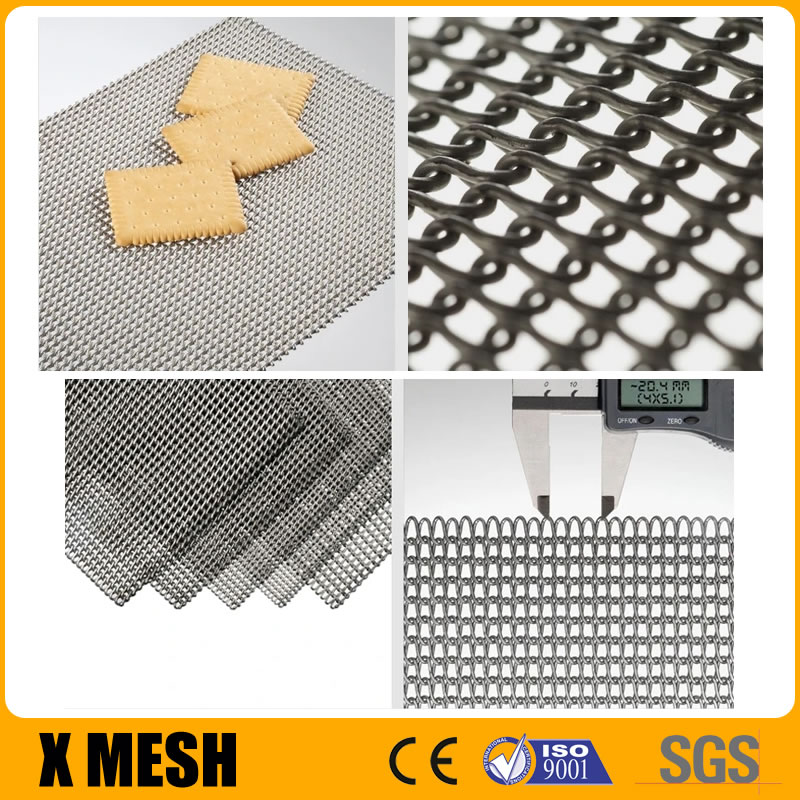

Our belts are designed with a lightweight, stratified metal spiral structure, offering a reduced thickness for low heat inertia and high strength. The belt width can reach up to 1.8 meters, suitable for temperatures up to 275°C.

- Belt Structure: Stratified metal spiral belt with a reduced thickness for low heat inertia and high strength.

- Surface Design: The belts feature a completely flat, smooth surface, achieved through a rolling process.

- Thickness: The belt thickness ranges from 2.2 to 3.0 mm, designed for high heat efficiency.

- Belt Width: Available up to 1.8 meters, accommodating large-scale industrial baking needs.

- Temperature Range: Suitable for use in environments with temperatures up to 275°C.

- Edge Type: The edges of the belt are either welded or bended for durability and safety.

- Material Quality: Made from high-quality carbon steel or stainless steel for long-lasting performance and resistance to wear and tear.

These specifications ensure the Biscuit Baking Belts are highly efficient, durable, and suitable for a range of industrial baking and cooking applications.

Common Specifications for Flat Rolled Baking Belt

- Tooling Pitch (mm): 8.2, 8.5, 8.2, 8.2

- Wire Diameter (mm): 1.2, 1.5, 1.3, 1.4

- Spiral Pitch (mm): 4.0, 4.5, 4.3, 4.4

- Belt Pitch (mm): 5.4, 5.2, 6.8, 6.7

- Belt Thickness (mm): 2.4, 3.0, 2.6, 2.8

- Weight (kg/m²): 7.0, 12.2, 7.4, 8.2

Advantages

The Biscuit Baking Belt provides a smooth baking surface, excellent air circulation and heat distribution, and high durability with low maintenance. Its design offers a uniformly flat carrying surface, ideal for even baking.

- High Strength and Stability: Ensures the belts can withstand the demands of continuous industrial baking processes.

- Low Heat Inertia: This feature allows for quick temperature adjustments, improving energy efficiency.

- Excellent Air Circulation and Heat Distribution: Vital for even baking and cooking processes.

- Long Service Life and Low Maintenance: The belts are designed for durability and ease of upkeep.

- Smooth Baking Surface: Ensures that products are baked uniformly, without sticking or uneven cooking.

- Corrosion and Rust Resistance: Especially in stainless steel variants, providing longevity in various environments.

- Flat and Uniform Carrying Surface: Essential for the consistent transfer and processing of baking goods.

Our packaging for Biscuit Baking Belts includes

Standard Bulk Packing: Efficient in cost and space, this method reduces the need for pallets, thus lowering packaging and shipping costs.

Customized Packing: Specifically tailored to client requirements, offering ease in handling despite higher costs.

Custom Labels: Personalized branding and identification for each shipment.

Warehouse Storage: Belts are stored in a spacious, clean, and dry warehouse, ensuring their optimal condition. Short-term storage services are also available.

These diverse packaging options are designed to meet a range of logistical and branding needs, guaranteeing that the belts are delivered in the best possible manner.

See pictures for examples

Biscuit Oven Conveyor Band

Rolled baking belts are essential for cooking delicious biscuits