Hebei Qijie Wire Mesh MFG Co., Ltd. is an expert in producing and selling Copper Alloy Aquaculture Mesh, essential for modern aquaculture systems. Made from a blend of copper and metals like zinc, aluminum, or nickel, this mesh is designed for optimal performance in various applications, including open-sea cages, ponds, and raceways. It’s especially popular for farming salmon and trout.

As professional designers, we meet standard customer needs and offer customization options for Copper Alloy Aquaculture Mesh. We produce four primary types, each tailored to specific requirements.

Material

Copper Alloy Aquaculture Mesh is made from a blend of copper and other metals, which provides it with unique properties suitable for use in aquaculture environments. The primary components of this mesh material include:

- Copper: The primary component, copper, offers excellent resistance to corrosion, especially in marine and freshwater environments. This is crucial for durability and longevity when the mesh is continuously exposed to water.

- Zinc: Often included in the alloy, zinc enhances the mesh’s resistance to corrosion, further improving its durability. It can also contribute to the strength of the mesh.

- Aluminum: Aluminum may be added to the alloy to increase the mesh’s strength-to-weight ratio. It makes the mesh lighter, which is beneficial for ease of handling and installation, without compromising its strength.

- Nickel: The addition of nickel can improve the alloy’s resistance to both corrosion and wear. It can also enhance the overall strength of the mesh.

- Other Metals: Depending on the specific requirements of the aquaculture application, other metals might be included in the alloy to fine-tune its properties. These could include elements like manganese or tin, which can further enhance certain characteristics like strength or ductility.

- The specific proportions of copper (Cu), tin (Sn), aluminum (Al), and zinc (Zn) in Copper Alloy Aquaculture Mesh material can vary based on the desired properties. It’s important to note that these percentages are approximate and can differ significantly based on specific requirements.

Copper (Cu): This is the primary element in the alloy, typically comprising the majority of the material. The copper content could be anywhere from 60% to 90%, depending on the other elements added and the required properties.

Tin (Sn): Tin is often added to improve corrosion resistance and strength. The proportion of tin can range from a few percent up to about 10%.

Aluminum (Al): Aluminum, when added, is usually in a smaller percentage, possibly around 5% to 10%. It’s used to enhance the strength and reduce the weight of the mesh.

Zinc (Zn): Zinc is also commonly used in copper alloys for its corrosion resistance properties. Its proportion can vary, but it might be in the range of 5% to 15%.

Copper Alloy Aquaculture Mesh Type

When comparing the four categories of copper alloy aquaculture mesh, each type presents unique characteristics and applications.

Let’s delve into a detailed comparative analysis:

- Copper Alloy Aquaculture Welded Mesh

Material: Composed of copper alloy wires, known for their corrosion resistance and strength.

Wire Diameter: Ranging from 2.5 mm to 4.0 mm, it strikes a balance between flexibility and robustness.

Mesh Size: The 25 mm to 40 mm size range is versatile for various aquatic species.

Mesh Type: The square mesh provides consistent opening size, crucial for maintaining predictable water flow and waste management.

Lifespan: A minimum of 5 years, indicative of good durability in aquatic environments.

Construction: The mesh is fabricated by welding at each wire intersection, enhancing strength and rigidity.

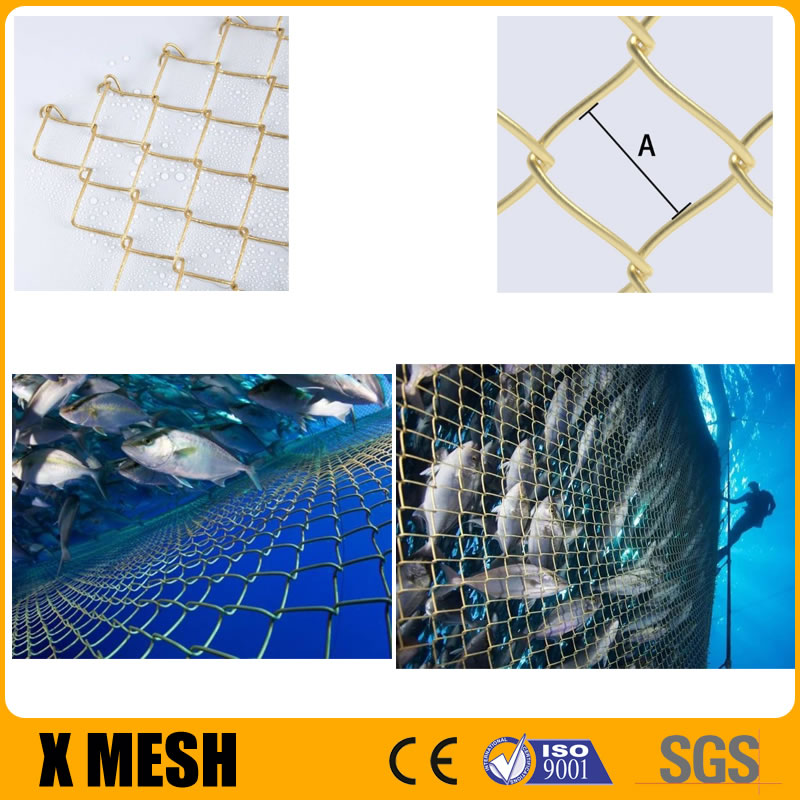

Applications: Best suited for static or semi-static systems that require high strength, such as in ponds or sheltered bays. - Copper Alloy Aquaculture Chain Link Mesh

Wire Diameter: Similar to the welded mesh, ensuring comparable strength.

Mesh Type: The diamond pattern allows for greater flexibility, adapting well to dynamic water conditions.

Lifespan: Ranges from 5 to 8 years, possibly longer in certain environments.

Design: The diamond pattern is typical for chain link designs, providing a balance of strength and give.

Flexibility: More pliable than welded mesh, making it ideal for open water systems facing waves and currents.

Durability: Exhibits good endurance against environmental stresses.

Mesh Size: Adjustable based on farming needs, offering versatility.

Applications: Frequently used in open sea cages and environments with significant water movement. - Copper Alloy Aquaculture Expanded Metal Mesh

Sheet Thickness: At 1 mm to 2 mm, this mesh is lightweight yet durable.

Mesh Size: The 25 mm to 40 mm range aligns with other mesh types for species versatility.

Mesh Type: Diamond-shaped, combining strength and flexibility effectively.

Open Area: A high open area of 73% to 76%, facilitating superior water flow and oxygenation.

Lifespan: At least 10 years, the highest among the four, reflecting its durable structure.

Manufacturing Process: Created by stretching a solid copper alloy sheet, resulting in a unique pattern.

Surface Area: The larger surface area is beneficial for filtration and water flow.

Applications: Suitable for diverse systems, including those needing efficient filtration. - Copper Alloy Aquaculture Crimped Wire Mesh

Wire Diameter: Ranges from 2.5 mm to 4.0 mm, indicating a strong build.

Mesh Size: The 25 mm to 40 mm dimension is consistent with others for species accommodation.

Mesh Type: Square, offering a rigid and strong structure.

Lifespan: At least 5 years, comparable to the welded wire mesh.

Design: Wires are pre-crimped before weaving, enhancing the structural integrity.

Texture and Rigidity: The texture provides a robust surface with good rigidity.

Strength: Highly durable with resistance to deformation.

Applications: Ideal for systems where structural strength is paramount, such as in large, heavy cages. - Comparative Summary

Strength and Durability: All types exhibit robustness, with expanded metal mesh leading in lifespan.

Flexibility vs. Rigidity: Chain link and expanded metal offer more flexibility, suitable for dynamic environments, whereas welded and crimped meshes are more rigid, ideal for static systems.

Mesh Type and Applications: Square meshes (welded and crimped) are great for uniformity and strength, while diamond-shaped meshes (chain link and expanded) excel in flexibility and water flow.

Environmental Suitability: The choice among these meshes depends on the aquatic species, the environmental conditions, and the structural requirements of the aquaculture system.

Each type of mesh has its niche, making the selection highly dependent on the specific requirements of the aquaculture operation.

Copper Alloy Aquaculture Mesh Uses and Features

Copper Alloy Aquaculture Mesh is a versatile, durable, and environmentally friendly choice for various aquaculture applications. Its ability to resist corrosion, prevent fouling, and ensure the health and safety of aquatic species makes it a preferred material in modern aquaculture practices.

- Uses of Copper Alloy Aquaculture Mesh

Marine and Freshwater Cages: It is extensively used for constructing cages in both marine and freshwater environments. This is ideal for farming a variety of fish species, including salmon, trout, and other commercially valuable fish.

Pond and Raceway Systems: The mesh is also used in pond liners and raceway systems for aquaculture, providing a controlled environment for the growth of aquatic organisms.

Shellfish Farming: It’s used in oyster and mussel farming systems, offering a durable structure for shellfish to grow on.

Protective Barriers: The mesh serves as a barrier against predators and helps in containing the farmed species within a designated area.

Filtration Systems: Its use in filtration systems helps maintain water quality by filtering out unwanted substances and organisms.

- Features of Copper Alloy Aquaculture Mesh

Corrosion Resistance: The copper alloy composition provides excellent resistance to corrosion, especially in salty marine environments, making it durable and long-lasting.

Anti-Fouling Properties: Copper naturally inhibits the growth of marine organisms like algae, barnacles, and mussels, reducing the need for frequent cleaning and maintenance.

Strength and Durability: The mesh is strong and capable of withstanding harsh environmental conditions, making it ideal for containing large numbers of fish or other aquatic species.

Environmental Friendliness: Copper alloy mesh is a more environmentally sustainable option compared to synthetic materials, as it doesn’t degrade into microplastics.

Improved Fish Health: The use of copper alloy mesh can lead to better water quality and circulation within the enclosures, contributing to the overall health and growth of the farmed species.

Customizability: The mesh can be customized in terms of mesh size, wire diameter, and panel dimensions to suit different aquaculture applications.

Reduced Maintenance: Its anti-fouling and corrosion-resistant properties significantly reduce maintenance efforts and costs.

See pictures for examples

QIJIE Copper Alloy Aquaculture Mesh Model CAAM-001

QIJIE Copper Alloy Aquaculture Mesh Model CAAM-002

QIJIE Copper Alloy Aquaculture Mesh Model CAAM-003

QIJIE Copper Alloy Aquaculture Mesh Model CAAM-004

The precise composition of the copper alloy used in aquaculture mesh can vary depending on the manufacturer and the intended use. This variability allows for the customization of the mesh to meet specific requirements of different aquaculture systems, such as varying levels of exposure to saltwater or the need for different levels of strength and flexibility. The alloy composition is carefully balanced to provide an optimal mix of durability, corrosion resistance, and physical properties for aquaculture applications.

Our personalized service provides online and phone consultations to tailor mesh structure and size to your specific needs. Each of our mesh categories features unique characteristics and applications, ensuring we can accommodate a diverse range of aquaculture requirements. This approach ensures that every client receives a mesh solution precisely suited to their unique situation, whether for different species, environmental conditions, or farming practices. Our commitment to customization and client-focused service positions us to effectively address the evolving demands of the aquaculture industry.